The Science Behind Heat Consumption Measurement

At the core of every modern heat meter lies a fundamental thermodynamic principle: q = m × c × Δt. This equation calculates thermal energy transfer by multiplying three variables:

- m = mass flow rate of circulating water (kg/h)

- c = specific heat capacity of water (1.163 Wh/kg·K)

- Δt = temperature difference between supply and return pipes

Validated by thermal metrology studies, this formula enables precise energy tracking with <2% margin of error in compliant systems.

How Flow and Temperature Data Combine to Determine Accurate Heat Usage

Heat meters cross-reference flow sensor readings with paired temperature probes, sampling data every 10–15 seconds. By analyzing over 2,880 measurements per hour, modern devices detect transient load changes that mechanical meters miss. Integrating ultrasonic flow measurement with platinum resistance thermometers achieves ±(0.5% + 0.01°C) accuracy—critical for fair billing in multi-tenant buildings.

The Physics of Thermal Energy Transfer in Hydronic Heating Systems

Because water holds four times more heat than air does, it works really well for moving thermal energy around systems. Take a typical setup where the water comes in at 70 degrees Celsius and leaves at 50 degrees. Each liter passing through actually moves about 23.26 watt hours of energy. The math behind this is pretty straightforward: multiply one kilogram of water by its specific heat capacity (around 4.186 kJ per kg per degree K) and then by the temperature difference of 20 degrees. When water flows turbulently in pipes (usually when Reynolds numbers go above 4000), the heat transfer gets much better. But watch out for those pesky air bubbles that get stuck in the system. They can cut down on thermal transfer efficiency by as much as 15%. That's why good system design matters so much, along with regular maintenance checks to keep things running smoothly.

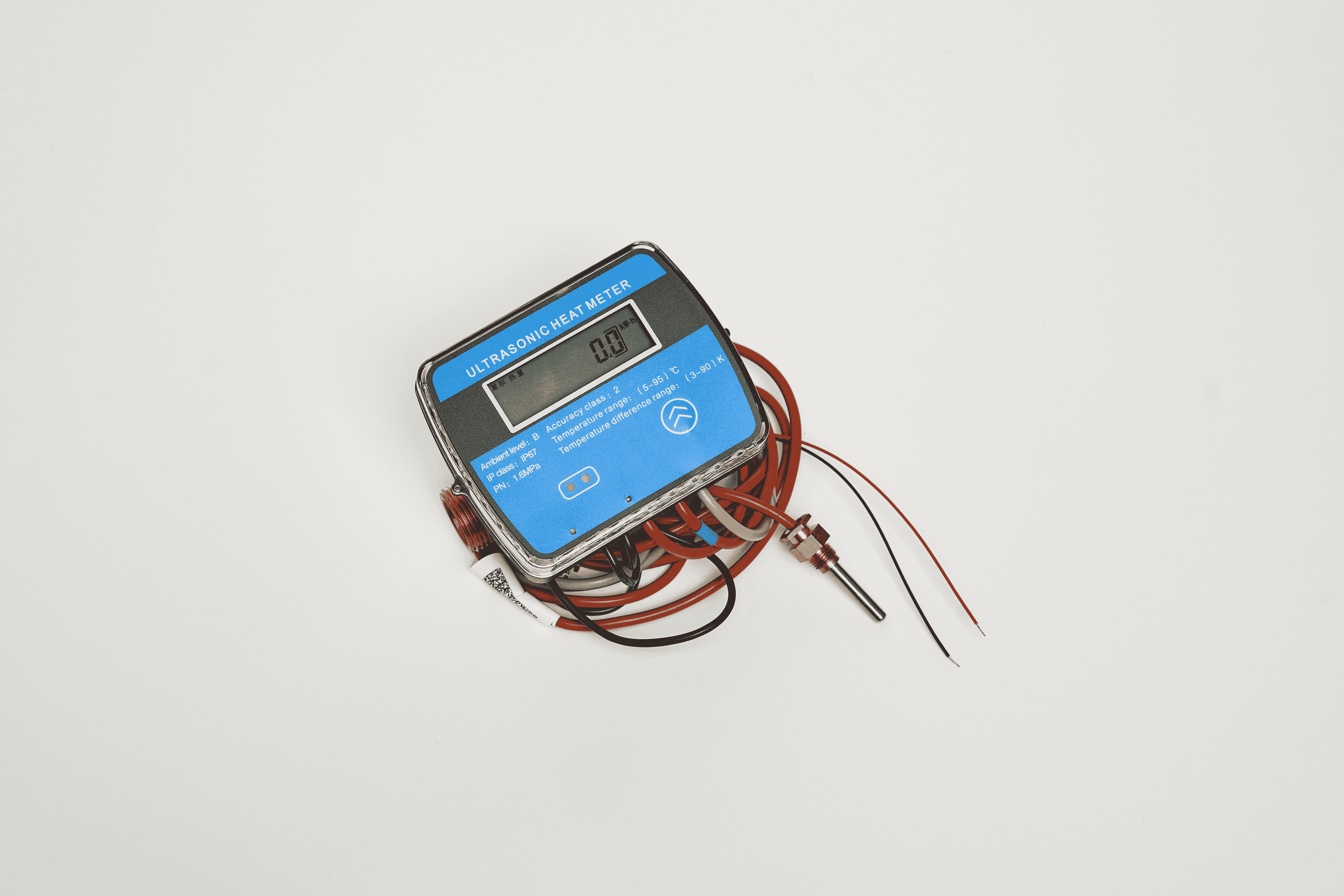

Key Components of a Heat Meter and Their Integrated Functionality

Core Elements: Flow Sensor, Temperature Sensors, and Integrated Calculator

Modern heat meters integrate three essential components:

- Flow sensors (ultrasonic or mechanical) measuring water volume in m³/h

- Paired temperature sensors monitoring supply and return lines with ±0.1°C accuracy

- Integrated calculators applying the q = m × c × Δt formula in real time

This configuration enables energy measurement precision down to 0.01 kWh. EN 1434-certified systems maintain ±2% accuracy, as confirmed in independent 2023 Euromet studies across 15 EU member states.

Precision Measurement of Flow Rate and Temperature Difference

Ultrasonic flow sensors offer ±1% accuracy using transit-time technology, outperforming turbine-based systems (±3%). Pt1000 temperature sensors resolve differences as small as 0.03°C. The integrated calculator adjusts for fluid properties, including water’s specific heat capacity (4.19 kJ/kg·K at 20°C) and density variations of up to 4% between 5°C and 90°C operation.

From Sensor Input to Real-Time Energy Display: Data Processing Workflow

Every 10–60 seconds, heat meters execute a closed-loop process:

- Flow sensor transmits volumetric data via pulse output (1 pulse = 0.1–10 liters)

- Temperature probes deliver signals through 4–20mA or Modbus RTU

- Calculator applies MID-compliant algorithms to time-stamped inputs

- Energy values (kWh) are displayed locally and transmitted via M-Bus or LoRaWAN

This integration reduces billing discrepancies by 74% compared to estimated charging models, according to the European Heat Metering Association (2022).

Ultrasonic Technology for Non-Invasive and Reliable Flow Measurement

Operating Principle of Ultrasonic Heat Meters

Ultrasonic heat meters work by sending high-frequency sound waves right through those metal pipes to figure out how fast the fluid is moving. Basically, there are two little devices stuck on either side of the pipe that shoot these sound pulses back and forth across the flow direction. When looking at how long it takes for signals to bounce upstream versus downstream, the meter calculates exactly what's going on inside without ever touching the actual liquid. Pretty neat really since this approach means no pressure drops happen during measurement and chances of messing up clean water systems drop dramatically too. Most plumbers appreciate this because their clients don't end up dealing with all sorts of maintenance issues down the road.

Transit Time Difference Method for Accurate Flow Detection

Transit time measurement works by using digital signal processing techniques to look at how fast ultrasonic waves move through a pipe when going with the flow versus against it. Basically, the sound waves going downstream just zip along faster compared to those heading upstream. Modern flow meters pick up on these tiny differences in travel time, which happen in fractions of a second, and then translate that into actual volume measurements. The smart part is that these devices have built-in software that adjusts for things like changing temperatures affecting fluid density or pipes expanding slightly. This means they stay pretty accurate, around plus or minus 1 percent, even when the flow gets really slow. Pretty impressive stuff for something so small and hidden inside industrial equipment.

Advantages Over Mechanical Meters: Durability, No Moving Parts, Low Maintenance

Ultrasonic meters work differently from traditional mechanical ones that use spinning parts like impellers or turbines which tend to wear out over time. Since they don't have any moving components inside, these devices cut down on maintenance expenses quite a bit something around half every ten years actually. Plus, they handle hard water much better without getting clogged up. The industry has seen enough evidence showing why ultrasonic tech stands out especially in district heating systems. These setups need equipment that lasts for years and can measure flow going both ways accurately, which regular meters just cant keep up with consistently.

Real-Time Energy Calculation and Smart Data Integration

Instantaneous Heat Energy Computation Using Digital Signal Processing

Modern heat meters use digital signal processing (DSP) technology to calculate thermal energy consumption as often as 500 times every single second. These devices take the basic data from sensors and turn it into those precise kWh readings we see on our bills, following the formula q equals mass multiplied by specific heat capacity multiplied by temperature difference. When looking at how these compare with older analog systems, there's a noticeable difference. The newer DSP meters only drift by less than 1% even when temperatures change quickly, which means they stay accurate no matter what kind of load fluctuations happen in the system. This matters a lot for facilities where heating demands can vary throughout the day.

Ensuring Data Accuracy in Dynamic Heating Conditions

Built-in validation algorithms continuously cross-check flow and temperature data to identify anomalies such as air entrapment or pump failure. A 2023 field study by the Energy Monitoring Association found DSP-enhanced meters achieved 99.2% accuracy in district heating networks with fluctuating flow rates.

IoT Integration With Smart Building Ecosystems

Advanced meters support communication protocols like Modbus, M-Bus, and BACnet, enabling seamless integration with building automation systems. According to a 2024 analysis in Smart Grid Data Integration, interconnected heat meters contribute to an 18% reduction in district heating waste through predictive load balancing and real-time demand response.

Factors Influencing Heat Meter Accuracy and Long-Term Reliability

Impact of Water Quality, Air Bubbles, and Flow Turbulence on Measurement Precision

Water that's hard on minerals can really mess with heat meter readings, sometimes cutting accuracy down by as much as 15%. When there's air trapped in the system, it changes how dense the fluid is and messes up those ultrasonic signals too. We're talking about errors around plus or minus 2 degrees Celsius here. And let's not forget about turbulent flows either they create all sorts of signal noise that makes measurements jump around. The good news? Some top quality meters fight back against these problems using self cleaning features and smart algorithms that adapt as conditions change. These advanced systems manage to stay within about 1.5% accuracy even when things get messy in real world situations.

Calibration Standards and Compliance With International Regulations (MID, OIML)

| Regulation | Scope | Accuracy Class |

|---|---|---|

| MID (Measuring Instruments Directive) | Residential billing | Class 1 (±2%) |

| OIML (International Organization of Legal Metrology) | Industrial monitoring | Class 0.5 (±1%) |

Adhering to established calibration protocols reduces measurement drift by 63% compared to uncalibrated units. A 2023 review of 12 European networks showed compliance extends recalibration intervals to 60 months in well-maintained installations.

Common Causes of Billing Discrepancies: Installation Errors and Lack of Maintenance

When pipes are not properly aligned, they cause about a quarter of all measurement errors because they mess up how fluids flow through them. Systems that get checked every three months tend to lose just 0.3% accuracy each year compared to those in rural areas where maintenance is lacking and drift reaches around 0.7%. Looking at seals regularly and making sure equipment can handle sudden temperature changes helps keep measurements stable within plus or minus 1% throughout their decade long lifespan. This was found in a big study looking at nearly 15 thousand ultrasonic meters across different heating districts.

Frequently Asked Questions

What is the equation used to measure heat consumption in modern heat meters?

Modern heat meters use the equation q = m × c × Δt, where 'm' stands for mass flow rate, 'c' is the specific heat capacity of water, and 'Δt' represents the temperature difference between the supply and return pipes.

Why do ultrasonic heat meters offer advantages over traditional mechanical meters?

Ultrasonic heat meters offer advantages because they have no moving parts, reducing maintenance costs and the chance of wear and tear. They also maintain accuracy even in challenging conditions and don't interfere with the water system when measuring.

What factors influence the accuracy of heat meters?

Factors like water quality (mineral content), air bubbles, and flow turbulence can influence heat meter accuracy. However, advanced meters combat these issues with self-cleaning features and smart algorithms to maintain high accuracy.

How often should heat meters be recalibrated?

Heat meters should adhere to established calibration protocols to reduce measurement drift. Well-maintained installations typically require recalibration every 60 months.

Table of Contents

- The Science Behind Heat Consumption Measurement

- Key Components of a Heat Meter and Their Integrated Functionality

- Ultrasonic Technology for Non-Invasive and Reliable Flow Measurement

- Real-Time Energy Calculation and Smart Data Integration

- Factors Influencing Heat Meter Accuracy and Long-Term Reliability

- Frequently Asked Questions